How to Make a Gada in Cold Weather

Tips on making Great Gadas

Steph and Bill Sorenson

Steph Sorenson’s YouTube Channel check it out.

40° Fahrenheit or 5° Celsius

How to Make a Gada in Cold Weather. With the colder weather (40° Fahrenheit or 5° Celsius) concrete takes longer to cure and we pour concrete in a garage that isn’t as heated as a house.

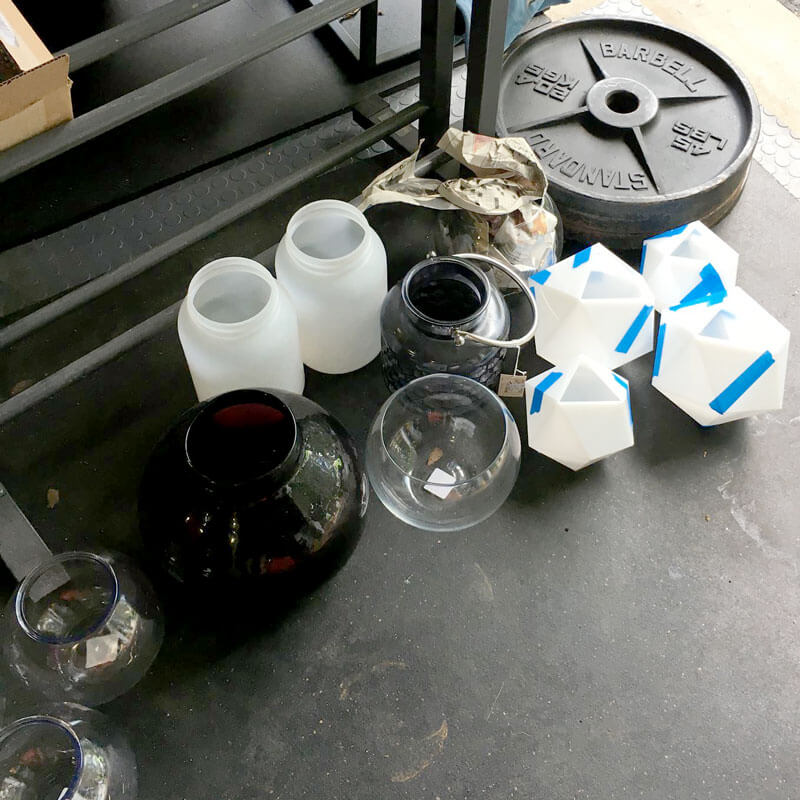

A collection of molds we found over the past year both online and at thrift stores

How to Make a Gada in Cold Weather

Concrete and Quikrete type brands need warmer weather to cure.

When you pour a concrete Gada in temperatures around 40° Fahrenheit or 5° Celsius, the drying and curing process is prolonged.

Hot water and soap

To help, we use warm/hot water when mixing concrete, and place the Gada in a mold on something to insulate it. Plywood works well.

Curing the Concrete

We then keep it warm by either heating the area or creating a small tent out of a tarp and heating that. After drying for a day, we bring them inside to finish curing and try and leave them alone for a couple more days.

After drying for a day, we bring them inside to finish curing and try and leave them alone for a couple more days

Getting Molds to Release Easily

When using glass or ceramic pot molds for Gadas, getting the mold off can be difficult.

Beware that glass and ceramic molds can stick to cured concrete. Separating them can take a long time, and you risk damaging the Gada itself.

Release Agent – Liquid Dish Soap

How to Make a Gada in Cold Weather

We use liquid dish soap on the inside of the molds to create a release agent. We brush all the surfaces with soap immediately before pouring.

Cover the surface, don’t leave any pools of soap in the bottom. Then, when it’s time to break the mold off, it’ll come off in large sections.

Wash the Gada once dried and cured to get all the soap off before finishing.

Sealing your new Gada

Once you have removed, the mold and your Gada has dried for 7 to 10 days. You have the option to seal it. We use Eagle Gloss Coat Clear Wet Look Solvent-Based Acrylic and apply 2 to 3 coats.

Preparation

How to Make a Gada in Cold Weather

Lightly rough the surface with sandpaper, and remove, blow or wipe off the dust.

Use a foam brush to paint on the sealer, watching for drips.

Follow the directions for in-between coat drying time. The last coat should dry to the touch after 4 hours.

The final coat produces a hard and clear surface for your Gada.

Follow the directions for in-between coat drying time

Before sealing, you can also stain or paint the concrete head. The sealer goes on last. We’ve been known to mix in metallic sprinkles to add colour and flash in the first seal coat, covering them in the next two. This sealer creates a sort of solid coating, solidifying all the concrete as well.

Bamboo or Wood handles

We have made gadas out of both bamboo and garden poles.

In cold weather, bamboo cracks the complete length of the gada.

We don’t have a solution for this, so now we use 1.25″ or 3cms garden poles for weights up to 20lbs, and 1.5″ or 3.5cms poles for heavier gadas.

It’s a little different feel but works well. Hopefully, we will solve the bamboo cracking, but until then, it’s wooden poles for us.

I would like to thank Bill and Steph Sorenson for taking the time to contribute the instructions and photographs on “How to Make a Gada in Cold Weather”

I would like to thank Bill and Steph Sorenson for taking the time to contribute the instructions and photographs on “How to Make a Gada in Cold Weather”Bill and Steph Sorenson have published an eBook guide. Click here…

Original Homemade Clay Pot Gada Mace Free Instructions. Click here…